Our technology

From lab to field, tested, proven, and deployed technologies

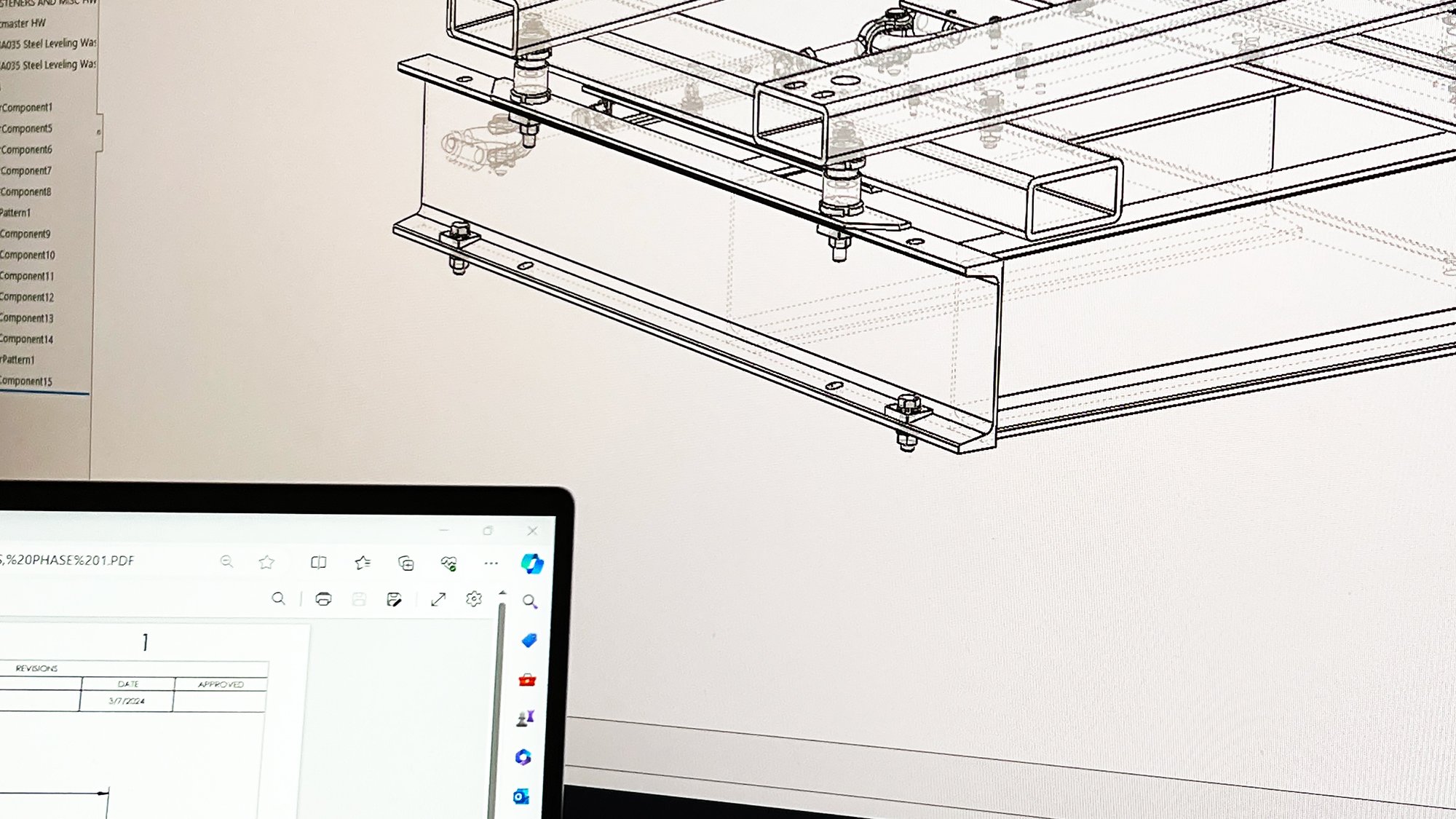

Modular DAC

Leo Series

The first U.S. DAC system designed for mass production

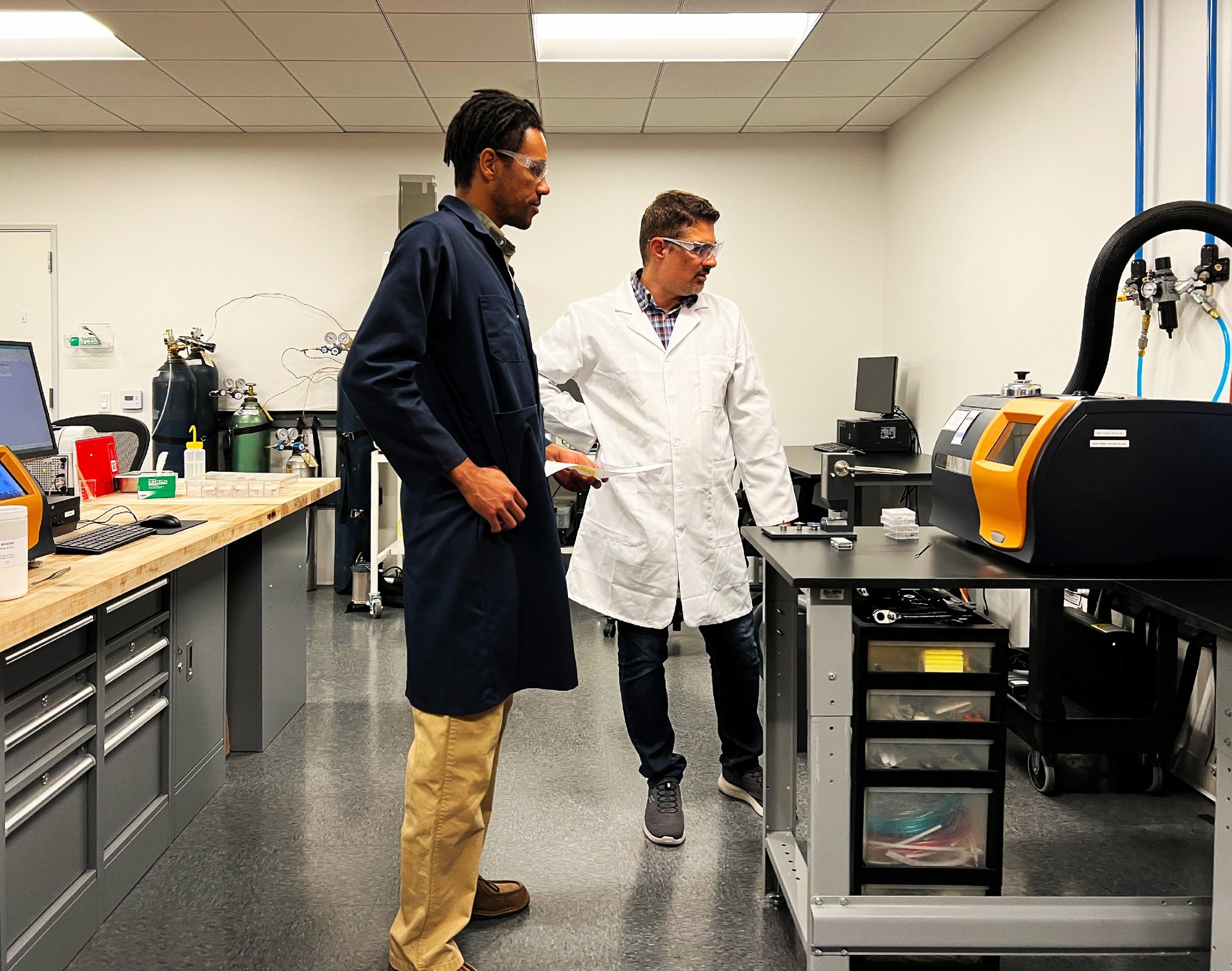

Our capabilities

What’s under our hood.

We’ve built a team and the capabilities to deliver end-to-end DAC projects from materials science to large-scale project development.

Materials science

Prototyping

Engineering

Manufacturing

Partnerships

Let’s face civilization’s greatest challenge together.

Roughly 100 billion tons of CO₂ need to be removed from the atmosphere by 2100. Reaching that goal will require a massive effort by the global community. Below are the areas in which we’re actively seeking partners.

Sorbents

If you are developing a sorbent that's well-suited for DAC, let us know. With an open systems architecture, we may be able to provide a rapid path to evaluation, manufacturing, and commercial deployment. Note that our DAC hardware platform is designed to accommodate a wide range of low-temperature solid sorbents.

Project deployment

We’re currently seeking partners in the following areas: DAC deployment for atmospheric carbon removal, geological CO₂ storage, sustainable synthetic fuels, and low-carbon concrete. Contact us if you’re seeking a DAC partner to supply upgradeable commercial DAC systems that can start small and scale to megaton levels.

Project financing

Over the next decade, we will require a significant amount of capital as we deploy megatons of DAC capacity. We're seeking to develop relationships with forward-thinking project investors that share our mission to decarbonize the atmosphere.